TW Logisistics

A company overview

EnquiriesAt TWL, we aim to work with our clients to find solutions.

TWL has a long tradition of handling and processing raw materials.

See current vacancies at TWL.

Latest News from TW Logistics.

At TWL our relationship with customers is paramount.

T W Logistics is a leading operator for the handling of metals, minerals and ferro alloys.

Whether the goods originate in the UK (for export or for use in the domestic market), or are imported through one of the UK's conventional or container ports, T W Logistics can provide a conveniently located packing facility, reducing expensive double handling costs.

We aim to make the logistical movement of goods as simple and smooth as possible.

TWL specialises in bulk materials handling, storage and logistics.

Container devanning and stuffing services are available.

TWL owns its own fleet of heavy goods vehicles.

TWL has the capability to load dry bulk.

Contact us for more information about our latest news stories.

Make an Enquiry

We are thrilled to announce the addition of this Twin Deck Vibratory Sieve to our production line. This state-of-the-art piece of kit is set to revolutionise our screening process with its exceptional features:

We’re excited to see the impact this advanced equipment will have on our operations and efficiency. Contact us today for more details on sizing, pricing, and availability.

We recognise that a significant proportion of bulk raw materials require some element of crushing or screening in order to meet client and end user specific requirements. T W Logistics operates six crushing plants capable of crushing products from 300mm to 2mm.

Larger sized materials can be accommodated by arrangement. Cargoes that can be crushed include ferro alloys, titanium, various minerals and refractory products.

TWL undertakes milling via continuous air swept grinding mills to produce flours to your specification. Our ball mill plant and equipment is equipped with ceramic and steel liners to accommodate a variety of products. Products that can be milled, subject to campaign size, include ferro alloys, refractory sands and minerals, limestone and clinkers, carbon products and certain metal and industrial slags.

The mills are operated by our experienced personnel and can produce standard powders from 325# to 200# or we can custom grind to specific requirements (60# - 400#). Our personnel ensure that the milled products are carefully monitored so as to ensure that specifications are maintained using in house testing equipment. Once milled the product can be packed as required. A full palletising and shrink or stretch wrapping and banding and labelling service is available in preparation for onward delivery. In addition to our larger mills, we also operate a small batch mill, which can be used on a semi-dedicated basis or to undertake small scale trials prior to full commercial production.

BFA is produced by the controlled melting of calcined bauxite within an electric arc furnace. Often used as an abrasive for applications such as metal preparation and blasting media, its thermal properties make this material an excellent raw material for refractory applications. It is a tough and hard material with high strength, making it an excellent abrasive grain for applications such as blasting media, metal preparation, lapping, polishing, and grinding.

Processing services provided by TWL include:

We recognise that a significant proportion of bulk raw materials require some element of crushing or screening in order to meet client and end user specific requirements. T W Logistics operate various screening plants, including double bed screens, power screens and pig iron grids, capable of handling bespoke, dedicated commodities and contract screening campaigns. Our facilities offer some of the best material screening services found in the UK.

Triple and quadruple bed screening can be undertaken by arrangement. Stainless steel and steel mesh screens are available to cater for different products. The screens can be set to produce size ranges and cuts to suit your requirements; producing finished sizes from 200mm - 0.2mm. Products screened include ferro alloys, pig iron, titanium, ash, grit and abrasives, aggregates, fertilisers, minerals, sands, wood pellets and salt. Materials Screening involves the separating granular alloys, ores and industrial minerals and splitting the feedstocks into various grades according to particle size. The screening process performance can be affected heavily by many factors, such as the characteristics of the material, the intensity of vibration, the size fraction of the feed and feed rate.

T W Logistics offer a wide range of storage options for bulk cargoes, construction materials, ferror and non-ferro alloys. In addition to this, we also have dry storage options for goods and materials such as plywood and palletised goods. Our Southern Warehouse at Wrabness is located close to port links in Essex being just 5 miles from The Ports of Harwich and Mistley. Our dry storage facility can handle a wide range of goods and associated packaging where a dry environment is required.

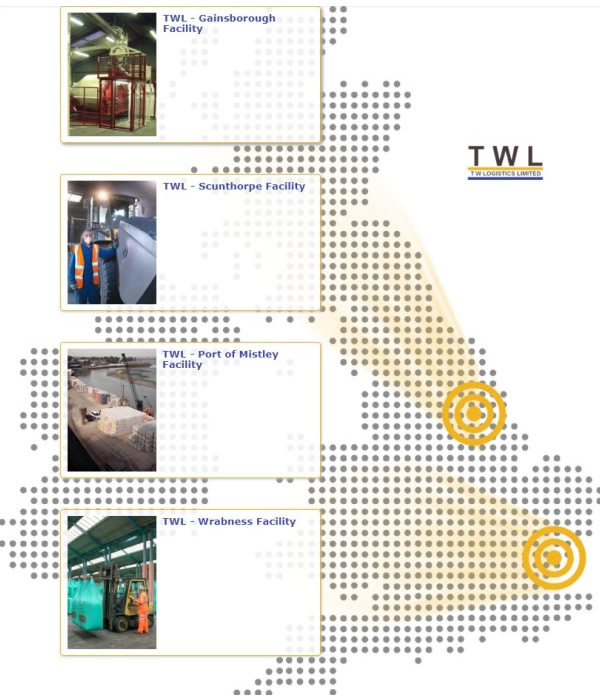

Operating from four well placed sites in the UK, we provide customers with an efficient logistical solution. Cargoes for the Midlands and the North of the UK can be handled at our Gainsborough and Scunthorpe facilities, with goods imported through dedicated River Trent berths or arriving in containers or road trailers through the main UK deepwater ports and container terminals. Cargoes for the Midlands, South and East of the UK can be handled directly at the Port of Mistley in Essex in coaster sized vessels, or received by container or road trailer through the major Southern container terminals at Felixstowe, Tilbury and London.

T W Logistics is fully operational as we head into the second month of the Coronavirus pandemic. All of our locations are open, undertaking all functions for our customers in the handling and processing of industrial raw materials and feedstock for national and international commodity traders and manufacturers.

We will continue to make substantial investments in processing equipment and specialises in the conversion of bulk raw materials and feedstocks into required formats for national and international manufacturers. Our staff are highly experienced and are here to help you, and we pride ourselves in continually exploring ways to adapt and invest in new processes in order to support our customers and their constantly changing markets.

We remain open for business and are continuing to offer and provide our full range of services to customers. As a major bulk materials' service supplier and processor, serving many industrial sectors and supply chains, we have an obligation to continue to trade - as confirmed by recent government advice and guidance, which we are continuing to monitor very closely.

Consequently, our four locations are currently fully operational and continuing to accept, store, process and deliver materials and cargoes, with minimal disruption to our day to day operations being experienced. Naturally whilst operating, however, the health and safety of our teams, customers and others remains our highest priority and, therefore, additional protocols have been introduced at our sites - with the strict observance of social distancing guidelines - our being committed to playing our part in helping prevent the spread of the COVID-19 virus.

Whilst our offices and sites remain open for business, and deliveries and collections are still possible - although with additional protocols in place - please note that, where they are able to, staff may be working from home, so we would ask for your patience, if necessary, at this time. Please, however, just speak with your usual TWL contact/s for any further details you may require.

We thank you for your continued support during this period of uncertainty, and wish you, your families, colleagues and friends, good health - STAY SAFE.

If your construction project has been put on hold due to the current pandemic, TWL are on hand to provide storage for your materials in both the North and South of England. Project Construction aggregates to give them their proper name includes a wide-ranging set of materials such as gravel, crushed stone or sand. These materials are mined and processed throughout the world and are heavily relied upon within the construction and engineering industries.

Processing services provided by TWL include:

T W Logistics is a leading independent operator in the UK for the handling, toll processing and distribution of industrial metals, minerals and ferro alloys.We also handle other commodities such as Aggregates, Bentonite, Chromite Sand, Fertiliser, Furnace Bottom Ash, Grain, Granite, Plastic, Solar Panels, Timber/Plywood, Wood Pellets and Zircon. Our new website offers a complete breakdown of each material type and the processes we offer.

The work is undertaken by our own experienced and professional personnel to ensure high standards of work are always achieved and maintained. We continue to invest in new plant to develop our scope of services in order to expand into new products and markets. We are always enthusiastic to progress your ideas, overcome challenges and respond to your requirements.

We have recently launched our new website offering a wider range of our services and materials handling solutions. TWL has been at the forefront of materials handling and processing as a leading provider in the UK. Our port operations strategically complement all of our materials handling activities with four locations across the UK.The website is specifically designed for all device formats offering a new section of material types that we process.

Established over 50 years ago, TWL specialises in the handling and processing of industrial raw materials and feedstock for national and international commodity traders and manufacturers. Whilst historically focusing on ferro alloys in the North and agri-products in the South of the UK, the company has expanded and diversified in response to market needs and today handles a wide range of bulk and packed products, offering a full range of cargo handling, logistics and toll processing services.

The tide tables for daily high and low tides for the Port Of Mistley are now in place for the full year 2019. BST commences at 01:00 on Sunday, 31 March and BST ends at 02:00 on Sunday, 27 October. Please note that the approach channel depth may vary due to periodic siltation. Prior to chartering for these berths, please check with the Port or with the Harwich Haven Authority. Please click the image to access the information.

TWL operates various packing lines and bagging stations across its facilities. Contract bagging and packing of Zircon Flour at TWL. Whether the goods originate in the UK (for export or for use in the domestic market), or are imported through one of the UK's conventional or container ports, T W Logistics can provide a conveniently located packing facility, reducing expensive double handling costs.

All our sites offer extensive covered and open storage to accommodate both the raw materials and the finished packed products prior to onward distribution. Examples of TWL packing lines:

A large brick shipment completed for the Port of Mistley this week with more to be processed and completed however no time for a breather, there is a brick shipment waiting to start discharging! The port is a NAABSA facility but regularly accepts 3,800 dwt vessels, as well as smaller vessels trading coast wise and across the North Sea. With a passage time from main North Europe ports to Mistley of 14 hours, Mistley makes the ideal location to transport goods competitively and efficiently.

The Port of Mistley offers ship owners and clients a competitive, efficient and cost effective alternative for UK imports and exports. Mistley Port is a NAABSA port. Full Tide tables can be found on our shipping information page. Please visit our port plan page for access access and quay facilities locations.

Ferro Alloys remain as our core business and we continue to be one of the leading independent operators in the UK for the handling and processing of bulk & packed Ferro Alloys. Historically, shipments would arrive at the UK deep sea ports such as Immingham & Hull, and were collected by truck or transhipped over-side into barges operated by T W Logistics for delivery directly into our riverside warehouses.

Our Northern sites at Scunthorpe & Gainsborough are ideally located for goods arriving by ship, truck or containers (delivered through local rail heads or collected from the ports). Our warehouse locations are very convenient for the main UK Ferro alloy users in the Yorkshire, Humberside, North East and Midlands.

We have recently published an online gallery on our Facebook page at www.facebook.com/twlogisticsuk covering our Port of Mistley operation locate in the Tendring district of Essex. Situated on the south bank of the River Stour, 10 miles from Harwich and Felixstowe, Mistley provides the ideal location for short sea and transhipment cargoes, with excellent links to Europe, the Baltic and Scandinavia as well as to London, the Midlands and the North. The port handles a diverse range of cargoes including bulk products (grain, fertiliser and agri- products, aggregates, industrial minerals, and recyclables), forest products, granite, steel products, metals, and various bagged, palletised and unitised cargoes.

TWL owns and operates the port of Mistley, offering ship-owners and clients a competitive and efficient solution for the import and export of goods. Situated on the south bank of the River Stour, 10 miles inland from Harwich, Mistley provides the ideal location for short sea, coastal and transhipment cargoes, with excellent links to Northern Europe, the Baltic, Scandinavia and the main UK hubs.

With four locations across the UK we are confident that TW Logistics Bulk can provide a complete solution for your Cargoes, Ferro Alloys, Bagged & Palletised, Materials Processing, Added Value Services, Cargo Handling, Logistics and Off Dock Storage & Warehousing. Our northern off dock, storage and warehousing The facilities are conveniently located close to the main UK motorway network, with links to the M180, M18, M62, and M1 and A1.

Vessel discharge, loading and handling operations are undertaken via dedicated approved berths on the River Trent and Humber. TWL handles a wide range of commodities, including ferro alloys, industrial minerals, refractory materials, and general bagged and palletised cargoes. 13,000m² of covered warehousing and open storage facilities (both adjacent and in close proximity to the port), bulk processing and packing facilities, customs approved warehousing, transport fleet, container devanning, container loading, full stock control and documentation ISO 9001 accredited, excellent main UK motorway links, bagged and palletised cargoes and refractory materials all handled.

T W Logistics operates the Wrabness storage and distribution centre, as well as offering transit warehousing at the Port of Mistley. In total between the two sites there is 17,000m² of secure, alarmed warehousing. The facilities specialise in the handling, storage and distribution of goods to and from road vehicle, particularly containerised and RORO traffic with short term, long term & strategic stocks, and dedicated warehouses available.

The warehouses are conveniently located close to the outward routes from main feeder ports of Felixstowe and Harwich, offering competitive rates for handling, storage and onward distribution. Wrabness storage facility is conveniently located close to the main UK container ports of Felixstowe, Tilbury, London Gateway & the RORO port of Harwich, with good road links to the A12 & the A14 serving London, the Southeast, the Midlands and East Anglia. The facility specialises in the handling, storage and distribution of goods arriving by road particularly containerised and RORO traffic and has developed a reputation for providing a timely, efficient and cost effective solution to off-set some of the higher costs associated with handling traffic of this type. Wrabness handles a diverse range of cargoes including fertilisers, dry bulks, packed, crated and palletised goods.

Operating through four sites in the UK, We aim to make the logistical movement of goods as simple and smooth as possible. All our facilities offer storage, handling, distribution and a range of ancillary support services for bulk and packed goods. In addition to our own fleet of bulk tipper and curtain side vehicles, we work with an excellent network of subcontract hauliers and pallet lines to supplement our own activities. This enables TWL to ensure that your goods are despatched and delivered as and when needed.

TWL haulage operates to all areas of the UK and we also arrange continental deliveries on behalf of our European and Global clients.

Storage Capabilities Include: long term, transit and dedicated storage for bulk and packed goods, secure covered warehousing, open storage, stock management and documentation services, COMAH, FIAS and TASCC approved warehouses, customs approved warehouses and ISO 9001 accreditations, extensive range of specialist processing available, container devanning and loading facilities, bagging and packing, cargo remediation, material handling including bulk, bags, rip and tip and tanker loading.

The Port Of Mistley has a long standing history and expertise in growing and developing such traffic flows through its own port at Mistley in Essex. Short sea shipping is the movement of cargo by sea between European ports; Due to the strategic East coast locations, the port of Mistley is particularly suited for traffic from Northern Europe, with rapid sea freight times from port to port.

The Port at Mistley can easily accommodate the size of vessels regularly trading such short sea routes including the extensive inland waterways network of Europe, and so can provide a rapid transfer of larger volumes of cargo on a ‘door to door’ basis. The port is well placed to take advantage of the particularly short sea crossing from North & continental Europe to the UK.

TWL provides a comprehensive range of toll processing services for industrial minerals, refractory products, metals and ferro-alloys. Located close to the UK east coast Humber ports we can offer complete logistics services from point of arrival to delivered end destinations. Please click the image to download the PDF.

Facilities include 30,000 square metres of undercover warehousing for bulk and packed goods complemented by 8 hectares of open storage. Toll processing services include materials crushing, screening, drying, milling and fine grinding. Materials processed include Ferro alloys for foundries - iron and steel manufacturers, Chromite sand, Pig iron, Silicon metal and other metals and ores Titanium, Zircon sand and other minerals for ceramic and refractory applications, Waste materials and recyclables, Agricultural products (fertilisers and grains), Abrasives, aggregates, ash, grits and slags.

The tide tables for daily high and ow tides for the Port Of Mistley are now in place for the full year 2018. BST commences 25/03/2018 BST ends 28/10/2018. Please note that the approach channel depth may vary due to periodic siltation. Prior to chartering for these berths, please check with the Port or with the Harwich Haven Authority. Please click the image to access the information.

The Port of Mistley has a set range of tide table information which is now available online through our website. Tide Table information can be accessed via the top menu bar under the "Ports" navigation section. Situated on the south bank of the River Stour, 10 miles from Harwich and Felixstowe, Mistley provides the ideal location for short sea and transhipment cargoes, with excellent links to Europe, the Baltic and Scandinavia as well as to London, the Midlands and the North.

The port handles a diverse range of cargoes including bulk products (grain, fertiliser and agri-products, aggregates, industrial minerals, and recyclables), forest products, granite, steel products, metals, and various bagged, palletised and unitised cargoes.

Our independently owned Port of Mistley has seen a number of investments over the years offering ship owners and customers a competitive, efficient and cost effective alternative for UK imports and exports. Cargo handling services include stevedoring & cargo handling, storage in quayside transit sheds, off dock storage & open storage, 3 x 500 tonne grain silos, container devanning and loading, 2 calibrated weighbridges, UK haulage access to all main routes, ancillary services included palletising, packing & remediation, powder tanker loading, rip & tip and full stock control and documentation.

Pilotage is compulsory unless PEC held, The Port of Mistley also offers 500m of quays available, 4 main operating berths, lay by berths available, berthing & mooring supplied by the port stevedoring, services for fresh water & waste disposal. Other services available locally include, ships agency customers clearance, cargo surveys & draft surveys sampling & testing.

The Port of Mistley provides significant off dock storage and warehousing facilities. Wrabness storage facility is conveniently located close to the container ports of Harwich and Felixstowe. Our facilities have good road links to the A12, serving London and the South East, and the A14 linking to the Midlands and the North. The facility specialises in the handling, storage and distribution of goods particularly containerised and RORO traffic. Wrabness provides a timely, efficient and cost effective solution for our customers. Wrabness handles a diverse range of cargoes including white goods, electrical items, packaged, palletised and bagged and bulk cargoes.

If the cargo or service you are considering is not listed, please contact us for assistance as we are always pleased to help. The warehousing and storage facility in Essex offers 12,000 m² of covered warehousing, bulk processing, packing, palletising and storage, UK distribution, container devanning and filling, customs approved warehousing, screening, stock control and all documentation being ISO9001 accredited and COMAH (lower tier) approved.

TWL is accredited and registered with a number of organisations and we have created a centralised area on our TWL website and also our dedicated Port of Mistley website. The accreditations page can be found in a new area on both websites called Accreditations. We are accredited and registered with ISO 9001 Quality Management System, Trade Assurance Scheme for Combinable Crops, UKWA United Kingdom Warehousing Association, RHA Road Haulage Association and the FIAS Fertiliser Industry Assurance Scheme.

We think the new visual presents a single graphical representation of our business model and the market sectors we operate in. T W Logistics is a leading independent operator in the UK for the handling, toll processing and distribution of industrial metals, minerals and ferro alloys. Operating through four sites in the UK, we aim to make the logistical movement of goods as simple and smooth as possible.

For more information on packing and bagging, please contact us at 01427 614551.

As part of our expanding marketing of T W Logistics we have created an infographic presenting the complete ports, processing and logistics solution provided by our company. This visual presents our complete range of services including crushing, screening, milling, packing and delivery.

We think the new visual presents a single graphical representation of our business model and the market sectors we operate in. T W Logistics is a leading independent operator in the UK for the handling, toll processing and distribution of industrial metals, minerals and ferro alloys. Operating through four sites in the UK, we aim to make the logistical movement of goods as simple and smooth as possible.

For more information on packing and bagging, please contact us at 01427 614551.

The primary areas of or activities have been summarised in easy to download PDF documents. Each document allows for a mini presentation focused on the Company, our Humber and Trent port operations, our Essex port operations, our Essex warehouse operations and also our significant expertise and facilities for materials processing and conversion.

We would request that you download the PDF’s and retain them as useful documents allowing for mini presentations of the products and services we offer. We also have the latest tide tables for our Mistley Quay facility. For sales and general enquiries call 01427 614551.

TWL have just invested in a new air packer to complement their existing packing and bagging lines at their Gainsborough site.

The benefit of the new packer is that we can now pack powders and finer grades of materials into small bags 10 kgs – 25 kgs.

Andy Bishop TWL’s Northern Operations Manager commented that this new air packer allows us to expand the range of products that we can now pack, as previously we were limited to more granular and coarser commodities. It is also quick to clean down between products, which is important so as to avoid cross contamination between products.

This additional equipment, together with our existing bagging lines, enables us to pack most products here at Gainsborough (except food grades) into bulk bags, small bags or drums ranging from 2000 kgs to 10 kgs.

For more information on packing and bagging, please contact us at 01427 614551.